Home > Services > Impact Abrasion Test According to EN17092

Impact Abrasion Test According to EN17092

AVAILABLE NOW

In our new, air-conditioned testing laboratory, we operate our own AART test rig and carry out impact abrasion tests for you in accordance to the Darmstadt method (EN 17092:2020).

As a licensed manufacturer of the AART (Advanced Abrasion Resistance Tester) test device, we can optimally use our many years of experience in connection with the test procedure when testing your products. Here, we see our focus in a testing strategy accompanying development or production. Without the financial burden of a certification procedure, you benefit from material testing already during your development and testing phase. This allows you to adapt your quality and process control at an early stage and reduce the costs of certification.

We carry out impact abrasion tests on your fabrics according to standardised specifications of the Darmstadt method (EN17092:2020) as well as according to your individual requirements. Various textiles and leather types can be tested.

You will receive documentation consisting of a test report and product evaluation.

After successfully completing the development phase, you can have your product certified by a Notified Body. A list of Notified Bodies located in your area can be found here (redirection to the page of the European Commission).

Your tests at us

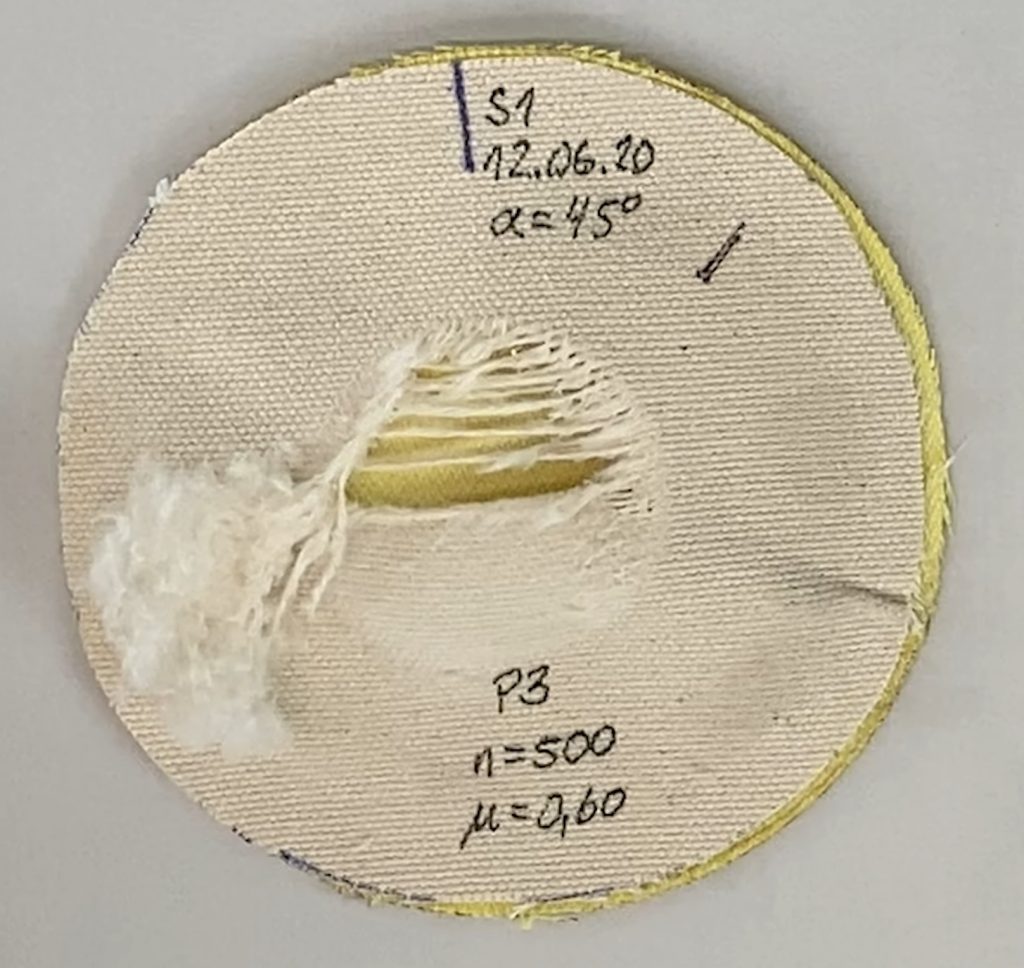

Depending on the desired protection class (AAA, AA, A, B) and the zoning, your test sample is tested at the corresponding target speed. A test cycle consists of three “trips” whereby 3 x 3 test samples are required. A total of 9 circular cut-outs (diameter Ø 125 mm) of your product are required for one test. We would be happy to make these cut-outs from your fabric for you.

We require from you:

- Target speed or target classification and zoning

- Sample of your fabric approx. (100 x 100) cm

- Indication of the warp/weft direction or type of weave

You’ll receive from us:

- Test report (target speed, time to standstill, distance to standstill, coefficient of friction).

- Product evaluation (fail/pass or failure behaviour)

- Photo documentation of the failure behaviour

Your advantages with us:

- Many years of experience with the Darmstadt method through our exclusive worldwide licence from the TU Darmstadt

- Constant test conditions due to air-conditioned test laboratory

- High flexibility

- Individual adaptation to your requirements

- Fast, uncomplicated and professional order processing

- Cost-effective implementation