Home > Products > Advanced Abrasion Resistance Tester (AART) > Delivery and accessories

Delivery

Unless otherwise agreed, the following delivery conditions apply:

- Delivery conditions according to Incoterms 2020: EXW for collection from the Reinheim plant.

- The delivery time for an AART is usually six months, provided that there is no longer any machine in stock.

- While shipping, the AART is screwed onto a special pallet that has grooves for tension belts. It can be moved with a pallet truck or forklift.

- The machine is protected by packaging film during transport.

- The dimensions of the machine can be found in the technical data.

Scope of delivery

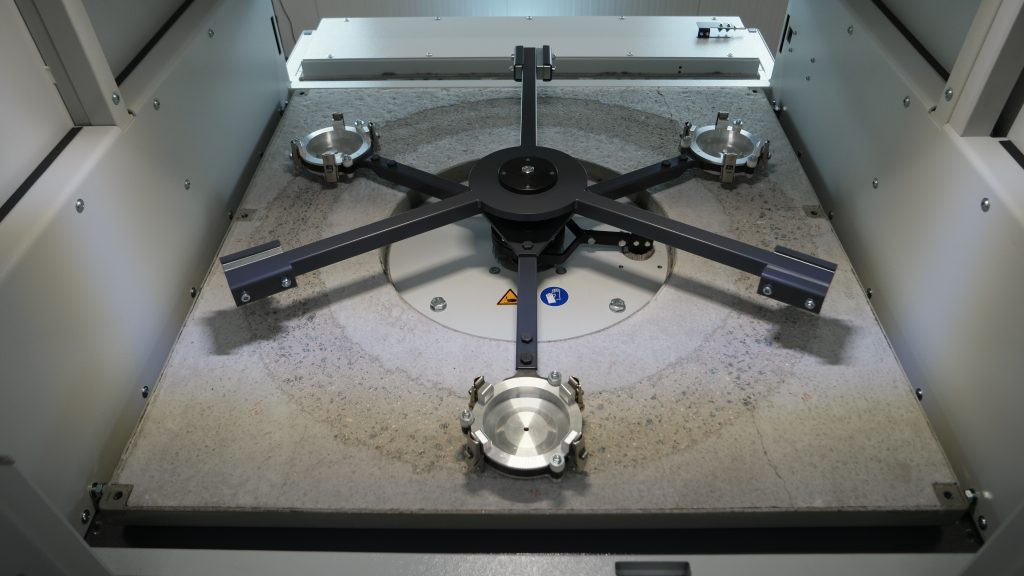

A starter set is supplied with each AART so that you can start your tests immediately after installation (see tutorials). The set consists of the following materials that you as a TRM customer can reorder at any time:

- 1 concrete road tile, calibrated according to EN 17092-1:2020 and installed in the AART

- 600 St. Para-Aramid laser cut-outs

- 3 pcs. rubber pads

Accessories

Concrete road tile

In close cooperation with concrete specialists, we manufacture and calibrate the concrete road tile according to the specifications of EN 17092-1: 2020 and ZTV StB 07. In this way, we can guarantee realistic and reproducible roadway properties.

During regular testing, the concrete road tile can be cleaned and a reduced coefficient of friction reactivated and recalibrated.

Despite years of research and customer engagement, no noticeable wear and tear on the concrete roadway has been found.

Para-Aramid cut-outs

During a test cycle, you need two para-aramid cut-outs as an intermediate layer in each specimen holder. If the protective effect of the para-aramid is used during a test, you can simply replace the damaged blanks. In addition, a “cleaning shot” (direct testing with para-aramid) frees the concrete roadway from heavy soiling and cleans it. Here, too, the dirty blanks must be replaced.

Rubber pad

To achieve the specified surface pressure, rubber pads are initially grinded into each sample carrier. Depending on the tests, wear and tear can necessitate replacement of the rubber pads. Since it is a product of technical rubber goods and these are subject to aging processes (embrittlement), we recommend replacing them after approx. One year. In the starter pack, the rubber pads are already mounted and grinded in each sample carrier.

Cotton Canvas reference material (not included)

For the clear determination of the friction coefficient, EN 17092-1: 2020 prescribes a reference material produced according to EN 388: 2016.

If you are interested, we will be happy to forward you the contact details of the sales partner or manufacturer. Just talk to us.

Go to technical specifications.